| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : SEEC

Model Number : Rolling mill

Certification : ISO

Place of Origin : China

MOQ : 10

Delivery Time : 3-6months

Packaging Details : Standard international package

Type 1 : Work roll

Material 1 : Cast iron and steel

Type 2 : backup roll

Type 3 : intermediate roll

process : Indefinite Chilled Double Poured Cast Iron

standards : ISO9001

Chilled Cast Iron Rolls for Indefinite Chilled Double Poured Cast Iron ICDP mill Rolls

Chemical Composition

| Roll name | C | Si | Mn | P | S | Ni | Cr | Mo |

| Cr-Mo infinite chilled cast iron roll | 3.20~3.70 | 0.80`1.20 | 0.60~1.00 | ≤0.20 | ≤0.10 | / | 0.60~1.20 | 0.20~0.60 |

| Ni-Cr-Mo infinite chilled cast iron roll(I) | 3.20~3.70 | 0.80`1.20 | 0.60~1.00 | ≤0.20 | ≤0.10 | 0.50~1.00 | 0.70~1.20 | 0.20~0.60 |

| Ni-Cr-Mo infinite chilled cast iron roll(II) | 3.20~3.70 | 0.60~1.00 | 0.60~1.00 | ≤0.20 | ≤0.10 | 1.01~2.00 | 0.70~1.20 | 0.20~0.60 |

| Ni-Cr-Mo infinite chilled cast iron roll(III) | 3.20~3.70 | 0.60~1.00 | 0.60~1.00 | ≤0.20 | ≤0.10 | 2.01~3.00 | 0.70~1.20 | 0.20~0.6 |

Physical Properties

| Roll name | Roll-body hardness HSD | Roll-neck hardness HSD | Tensile strength Mpa |

| Cr-Mo infinite chilled cast iron roll | 55~70 | 35~55 | >160 |

| Ni-Cr-Mo infinite chilled cast iron roll(I) | 60~72 | 35~55 | >160 |

| Ni-Cr-Mo infinite chilled cast iron roll(II) | 62~72 | 35~55 | >160 |

| Ni-Cr-Mo infinite chilled cast iron roll(III) | 65~75 | 35~55 | >160 |

Metallographic Structure

| Roll name | Metallurgical structure |

| Cr-Mo infinite chilled cast iron roll | Pearlite + cementite + a little graphite |

| Ni-Cr-Mo infinite chilled cast iron roll(I) | Pearlite + cementite + a little graphite |

| Ni-Cr-Mo infinite chilled cast iron roll(II) | Fine pearlite + cementite + a small amount of graphite |

| Ni-Cr-Mo infinite chilled cast iron roll(III) | Type body + cementite + a small amount of graphite |

Indefinite Chilled cast iron roll for rolling mill

For the finishing stands of continuous rolling mill of strip and bar, the pre-finishing stands of high speed wire, the intermediate and the front of finishing stands of small section, also utilized in thin plate and straightening roll.

| Grade | Hardness(HSD) | C | Si | Mn | Ni | Cr | Mo |

| Indefinite-I | 60-70 | 3.0/3.5 | 0.5/1.0 | 0.5/1.0 | 0.5/1.0 | 0.5/1.0 | 0.2/0.6 |

| Indefinite-II | 62-72 | 3.0/3.5 | 0.5/1.0 | 0.5/1.0 | 1.0/2.0 | 0.5/1.0 | 0.2/0.6 |

| Indefinite-III | 65-75 | 3.0/3.5 | 0.5/1.0 | 0.5/1.0 | 2.0/3.0 | 0.7/1.2 | 0.2/0.6 |

| Indefinite-IV | 70-85 | 3.0/3.5 | 0.5/1.0 | 0.5/1.0 | 3.0/5.0 | 1.0/2.0 | 0.2/0.6 |

| Hardness of shell | HSD60-85 |

| Hardness of neck | HSD35-48 |

| Tensile Strength of core | ≥450Mpa |

|

|

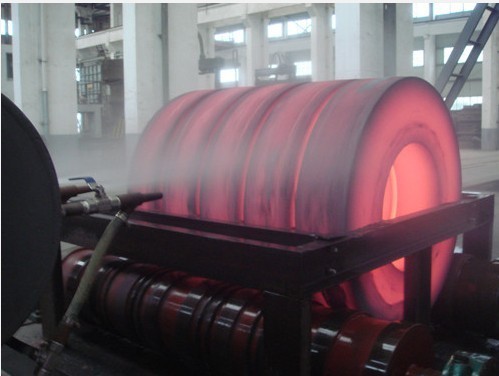

Professional Cast Iron Roller and Double Poured Cast Iron ICDP roll for rolling Mill Images |